Austchrome has the proven experience to deliver advanced, experienced and customer focused solution packages.

We are adaptive and with ever-changing technology this allows us the ability to improve the way we provide our solutions and technical insight.

We service industries such as

- Mining

- Agriculture

- Defence

- Heavy Industry

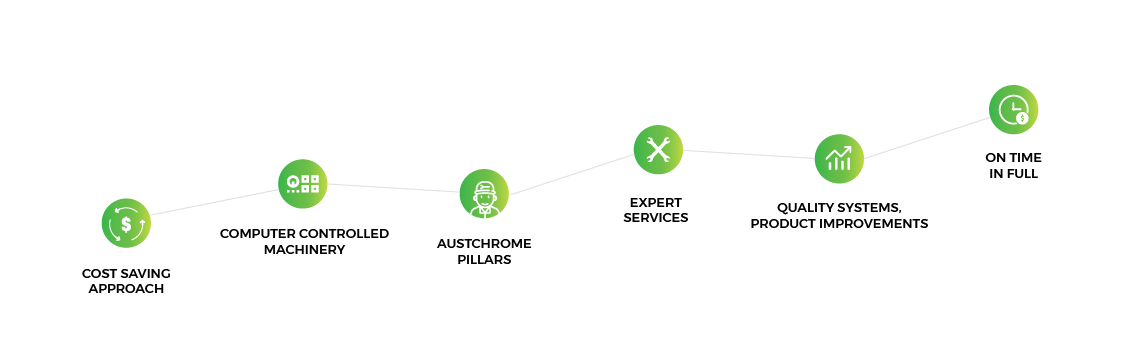

Our Process

Our 6 part process for delivering innovative solutions for our customers.

Cost Saving Approach

Our team operates modern equipment and have built efficient practices throughout the rebuild process. We can repair to your requested scope only and offer both OEM and aftermarket parts to help you control repair costs.

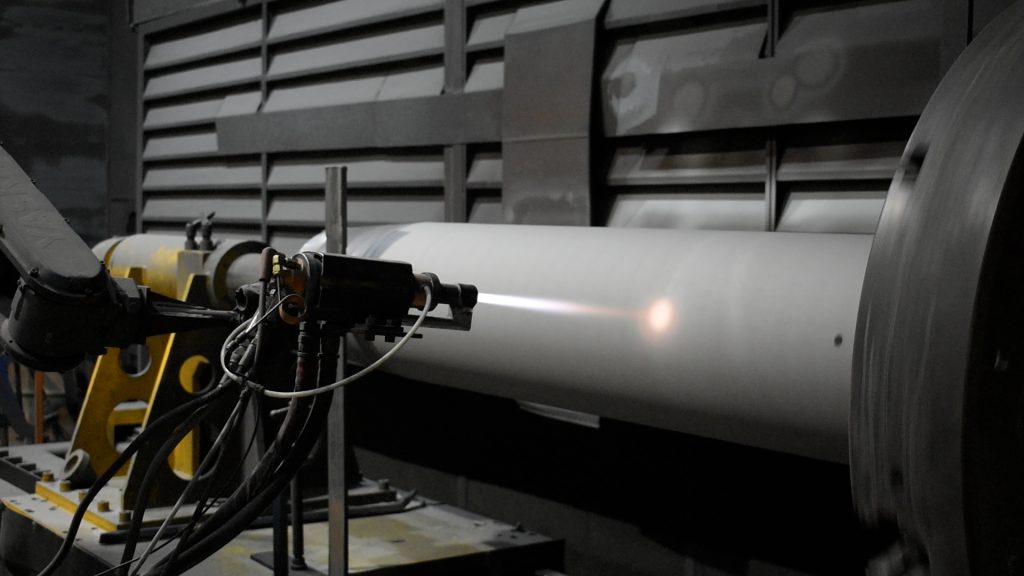

Computer Controlled Machinery

We have a suite of modern CNC machines and robotics, enabling us to provide the best quality product whilst maintaining the highest efficiency through process automation.

Austchrome Pillars

Our 5 key areas of Austchrome services support the business whether we overhaul or manufacture. These areas are Repair & Service, Industrial Chroming, Thermal Reclamation, Engineer & Manufacture and Paint & Pack.

Expert Services

Delivering services for over 25 years, our knowledge and expertise in the craft of machining, chroming and repair is unmatched. We provide the best industry product knowledge and service across all our product offerings, supported by highly skilled and valued staff.

Quality Systems, Product Improvements

Our robust Safety & Quality Management systems and continuous improvement programs enable delivery of high-quality products with minimal disruption through non-conformance. We hold ISO accreditations for Quality, Safety & Environment.

On Time In Full - OTIF

Our goal is always customer component delivery OTIF as per expectations. This results in less machine downtime and is underpinned by our cost saving approach. We back our workmanship and products with an extensive warranty.

Our team operates modern equipment and have built efficient practices throughout the rebuild process. We can repair to your requested scope only and offer both OEM and aftermarket parts to help you control repair costs.

We have a suite of modern CNC machines and robotics, enabling us to provide the best quality product whilst maintaining the highest efficiency through process automation.

Our 5 key areas of Austchrome services support the business whether we overhaul or manufacture. These areas are Repair & Service, Industrial Chroming, Thermal Reclamation, Engineer & Manufacture and Paint & Pack.

Delivering services for over 25 years, our knowledge and expertise in the craft of machining, chroming and repair is unmatched. We provide the best industry product knowledge and service across all our product offerings, supported by highly skilled and valued staff.

Our robust Safety & Quality Management systems and continuous improvement programs enable delivery of high-quality products with minimal disruption through non-conformance. We hold ISO accreditations for Quality, Safety & Environment.

Our goal is always customer component delivery OTIF as per expectations. This results in less machine downtime and is underpinned by our cost saving approach. We back our workmanship and products with an extensive warranty.

The Austchrome Difference

Our People & Customer Relationships

Our Austchrome team values delivering high-quality products and customer support. Our team works collaboratively with our customers to ensure we understand their needs, before developing tailored repair solutions and proposals.

On Time – High Quality

We provide complete repair solutions, not just services. We get to know our customers’ businesses and work closely with them, to provide options that reduce ongoing maintenance costs and improve product performance and componentry life.

Safety

High standards are not just something we aspire to. Austchrome is committed to best-practice industry stands and holds third party accreditation to international standards in Environment, Health & Safety and Quality.

Modern & Lean

Lean manufacturing principles have been embedded into our business and operational approach, including all workshop facilities process and equipment set up. The resulting efficiencies drive our team’s performance, visible team culture, and ability to consistently deliver on time and in full.

Workshop & Technical

Our workshop operations team brings together qualified fitters, machinists and boilermakers who have proven skills to undertake quality, timely work. Our technicians’ skills are supported by strong operational procedures to ensure the quality we have delivered over decades is implemented into every job.

Cost saving approach

By offering both OEM and aftermarket parts and repair options, we can help you control cost.

Projects we’ve worked on

Hydracrowd Hydraulic Cylinder: Repaired, Serviced & back into Production

Our client operates as fleet of five Cat 7495 HydraCrowd electric rope shovel excavators on mine sites within the Bowen Basin.

Customer was saved 40 days after only a 10 day turnaround time on leg cylinders

THE CHALLENGE A multinational mining company approached Austchrome to overhaul a large quantity of their underground longwall support cylinders from

Hydraulic repairs and maintenance saves customer critical hours

THE CHALLENGE We were recently contacted for an urgent job by our client who provides hydraulic repair and maintenance services

Providing a broad range of in-house reclamation and reconditioning solutions throughout Australia and Indo-Pacific regions for over twenty five years.

We work collaboratively with our customers to ensure we understand their needs. We aim to reduce costs and maximise componentry performance through tailored innovative solutions.

We are a company built by our people. Are you interested in joining a highly-skilled team that delivers innovative solutions for customers?

Industry Insights

Expert Hydraulic Cylinder Repair Services in Mackay and the Bowen Basin by Austchrome

Austchrome are the experts in hydraulic cylinder repair, service and reclamation services in Mackay and the Bowen Basin.

Austchrome’s Apprenticeship Program: Setting Up Future Tradespeople for Success

At Austchrome, we’re thrilled to announce the commencement of our new apprentice onboarding program.

Real Mates Talk at Austchrome

People often overlook the ‘Heath’ in Workplace Health & Safety, but the most significant health concern that is often missed

Contact us to get a quote

Ready to get started? Send us a few details and our team will be in touch.